ANN ARBOR, MI

A recent study by the Electronic Research Department provides groundbreaking insights into how polystyrene beads can be sintered to form highly ordered inverse opal (IO) structures—porous materials used in optics, catalysis, and thermal management. The research explores how the sintering process shapes the morphology of copper inverse opals (CIOs), highlighting the critical role of polymer characteristics and processing conditions.

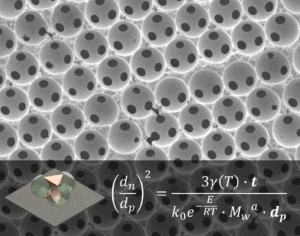

Using colloidal polystyrene particles of three different sizes (3.0, 4.0, and 5.3 μm), the team conducted 15 sintering experiments to identify optimal conditions for forming well-connected CIO networks. Through a newly developed theoretical framework, the researchers applied a generalized form of the Mark–Houwink equation—commonly used in polymer science—to understand how molecular weight and particle size govern the size of inter-particle interfaces (neck) during sintering. Remarkably, they discovered that the square of the neck-to-pore diameter ratio, (dn/dp)², increases linearly with sintering time in its early stages, confirming theoretical predictions.

This work offers a predictive tool for designing IO structures by linking polymer molecular weight, particle size, sintering time, and sintering temperature to final pore architecture. The findings empower researchers and engineers to tailor inverse opals with precision, opening new possibilities for high-performance materials engineered through controlled sintering of polymer templates.

Please see the complete work published in Langmuir